Our scope & method

Blueprint is your partner from design to completion, and we complete all the scopes we touch.

Design for manufacturing

Blueprint will review constructability, detect and resolve system clashes, and coordinate your design in 3D with your architect, structural and mechanical engineers, and your general contractor.

Blueprint project managers and production engineers will direct a real-time shop drawing process in a 3D production software, that will ultimately produce machine files to precisely fabricate your project.

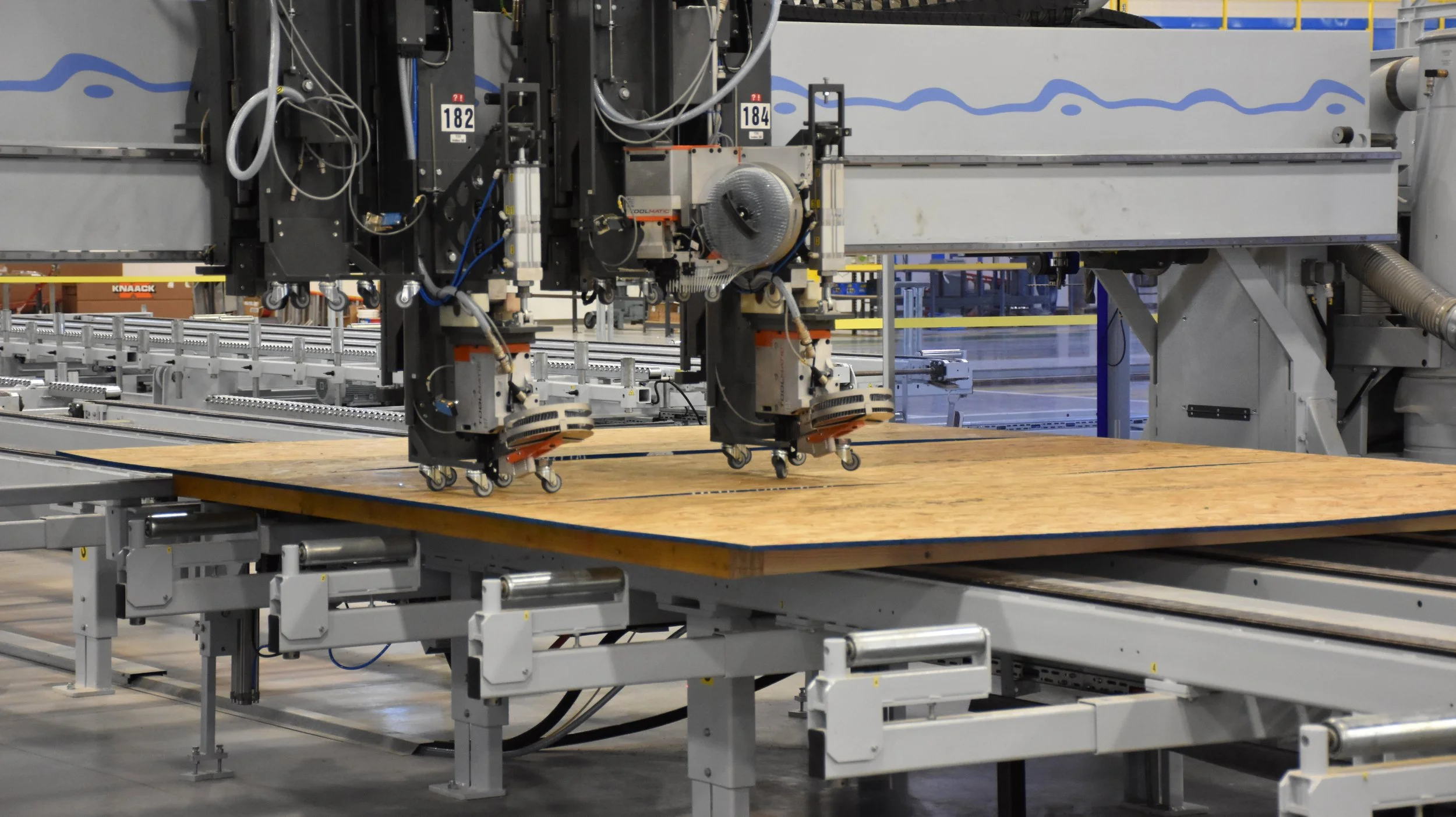

Production

Wood-framed wall, floor, and roof panels are produced efficiently in our 200,000 sf production facility utilizing state-of-the-art CNC machinery to cut, fasten, drill, and rout panels to accommodate your projects mechanical, electrical and plumbing rough-in.

We significantly reduce waste by utilizing optimization software and lumber selection.

Prior to leaving our production facility, exterior windows and doors are installed, as well as a significant portion of the MEP.

Mechanical, Electrical, Plumbing (MEP)

Blueprint will review constructability, detect and resolve system clashes, and coordinate your design in 3D with your architect, structural and mechanical engineers, and your general contractor.

Blueprint project managers and production engineers will direct a real-time shop drawing process in a 3D production software, that will ultimately produce machine files to precisely fabricate your project.

Rough Carpentry

Blueprint delivers a turn-key framing package, which consists of the entire-wood framed structure including sheathings, weather resistant barrier, and factory installed windows and exterior doors.

Passive House, net-zero energy, and other high-performance buildings will typically have dense-packed insulation installed by machine. Blueprint can deliver these projects with an air-tight building envelope under a single contract and single point of responsibility.

Logistics

The project is transported to your project’s site utilizing just-in-time methodology, reducing the need for large on site staging areas.

By controlling panel sizes, we can use standard 53’ trailers, which do not require oversize load permits nor escort vehicles.

Blueprint provides all site material handling equipment to include assembly crane and forklifts as necessary.

Field operations

Blueprint maintains responsibility for the installation of its product. Field operation teams are staffed by Blueprint construction professionals trained in the Blueprint Method. They are organized as project superintendents, trade supervisors and senior trade mechanics (frame assembly and MEP).

Blueprint supervisors are augmented with regional, labor only subcontractors who seek a new subcontracting model and have demonstrated a willingness to learn the Blueprint Method.

In addition to being faster than traditional building solutions, Blueprint’s on- site workforce headcount is as much as 40% smaller significantly reducing the carbon footprint of our construction operations.